About Us

Professional Precision Parts Manufacturer and Supplier

Established in 1996, HF-TI is a Taiwan-based manufacturer and supplier of precision zinc die casting, aluminum die casting, injection molding, stamping parts, machined parts and other customized products.

Especially for precision die casting and thin shell products, the core of HF-TI lies in the strong background of the molding technology team, which enables it to be a strong supplier and the best partner.

Our purpose is to provide the best service, high-quality products and one-stop solution services to all our customers, establish long-term cooperative relationships, and achieve success and growth together.

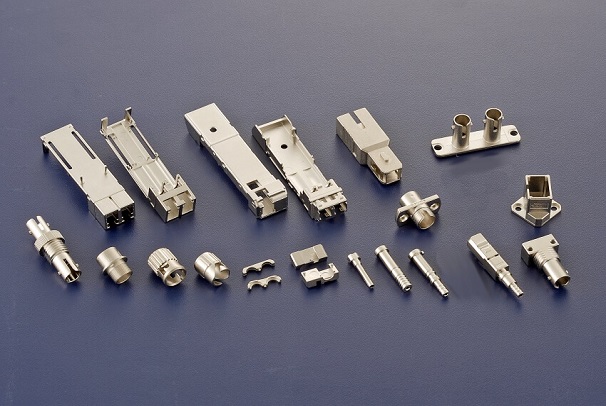

Our Products

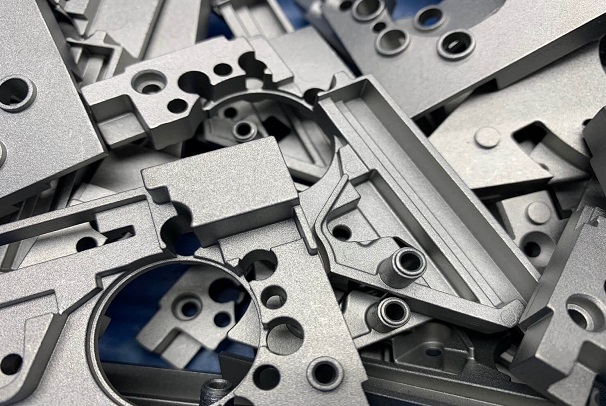

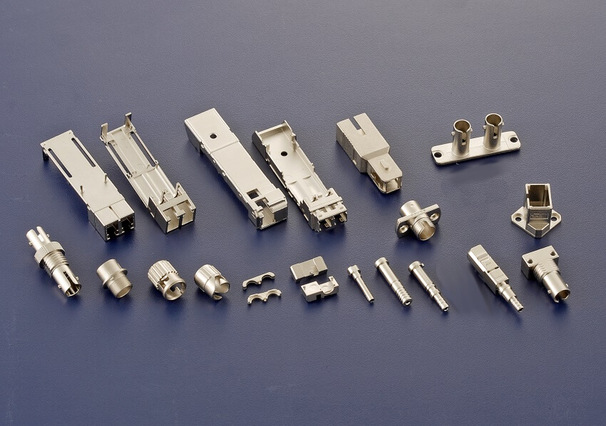

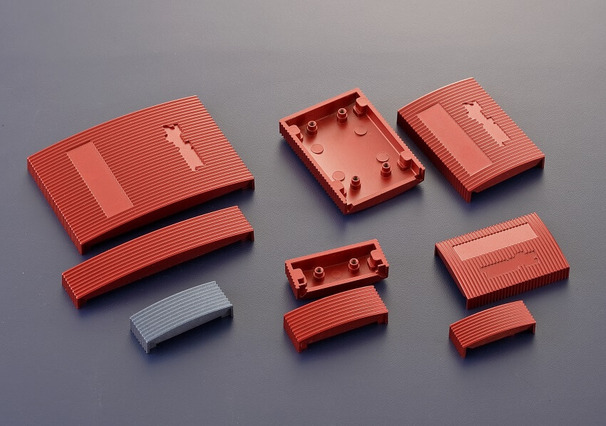

The products produced by HF-TI Company include zinc die casting parts, aluminum die casting parts and plastic injection products, CNC parts, stamping products for optics, electronics, optical communications, computers, mobile phones, antenna connectors, hardware, etc.

Our Service

We can provide integrated solutions for self-model proofing, mold design, mold opening, small-scale testing, mass production, post-processing, surface treatment and other consistent operations according to customer needs; in order to save customers' time and increase efficiency.

Our Production Equipment

The zinc alloy die-casting machine equipment ranges from 25 tons to 110 tons. It can be configured according to the different needs of customers. High-precision measuring instruments and machinery are imported to ensure that the products meet the needs and trust of customers.

Quality Control

We are committed to continuous improvement and control of quality, and have obtained ISO 9001 and ISO14001 quality certification systems. Our quality control process includes dimensional inspection, material testing, functional testing and visual inspection to ensure that each product has excellent performance and durability.

HF-TI Technical Skills

Mold Design

HF-TI has more than 30 years of rich experience in mold design.

We can provide customers with design and production suggestions and design efficient and reliable molds to improve production efficiency and meet high-standard, high-quality, and precision needs.

Mold Making

DFM: In the early stages of development, HF-TI can provide DFM feedback to customers, reducing the number of mold repairs and shortening the mold production time.

High-quality materials: To reduce wear and extend the service life of the mold, HF-TI selects the highest quality materials to make the mold to ensure the durability and performance of the mold.

Mold maintenance: To ensure the long-term use and superior performance of the mold, mold maintenance is crucial. HF-TI will perform mold repairs and regular maintenance to ensure that the mold maintains optimal performance during long-term use and reduces downtime.

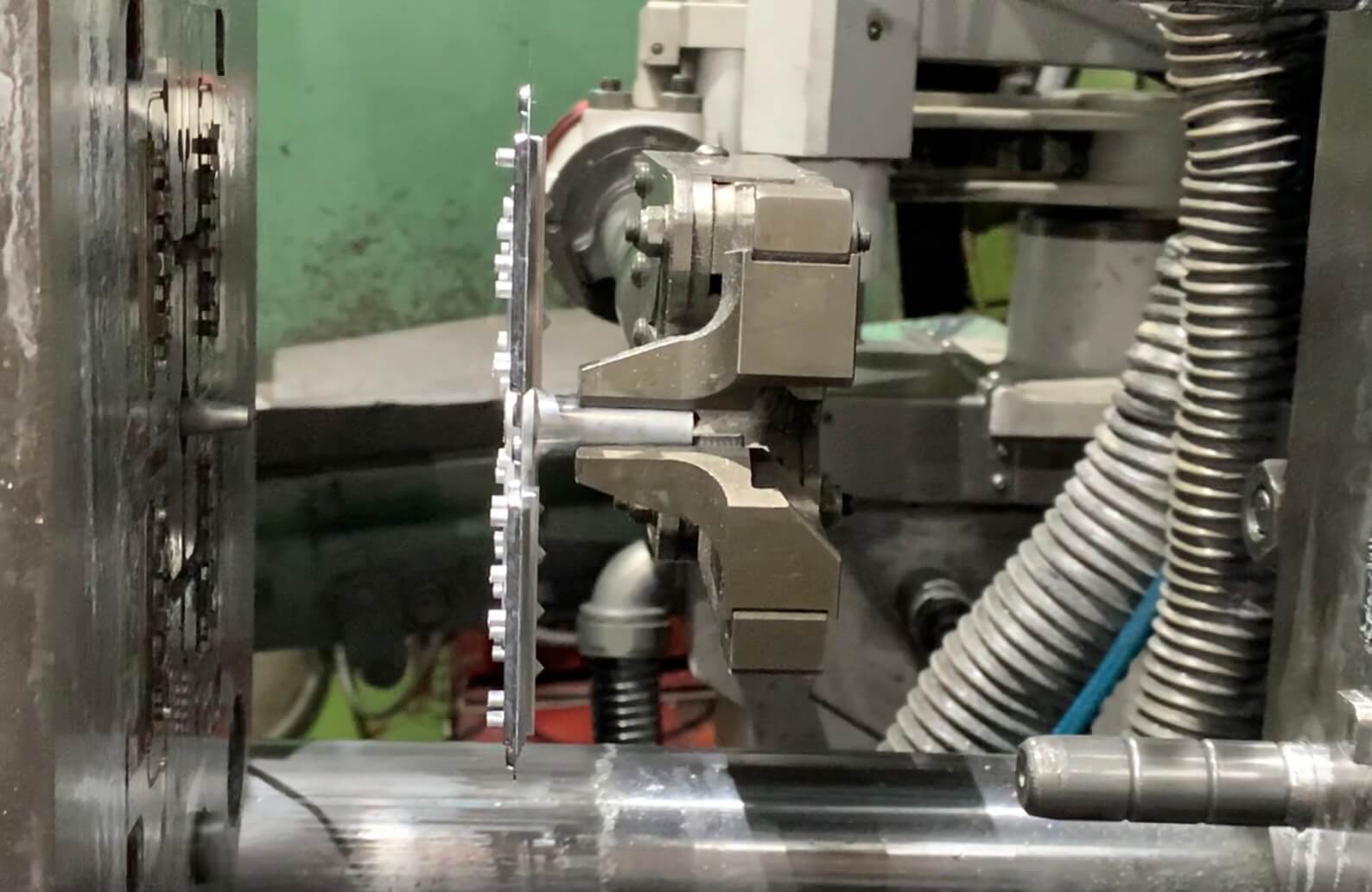

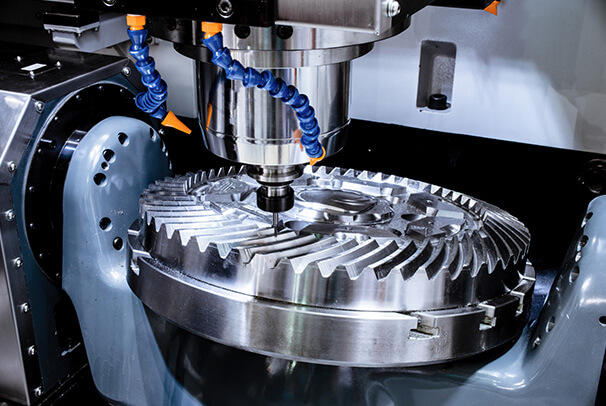

Die Casting Production

HF-TI has hot zinc alloy die-casting machines ranging from 25 tons to 110 tons, which can be configured according to the different needs of customers.

It is also equipped with high-precision measuring instruments and machinery to ensure that the products meet customer needs and trust.

Secondary Processing & Surface Treatment

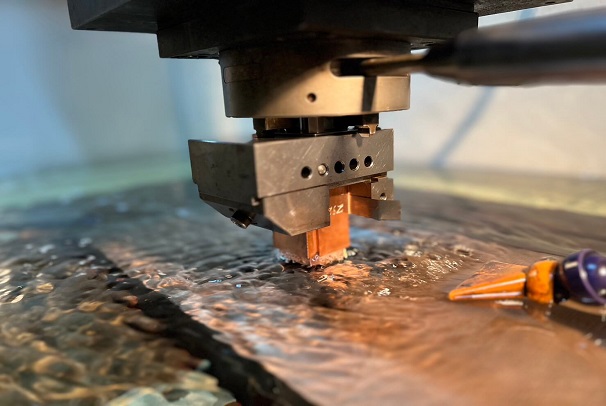

Electric Discharge Machining

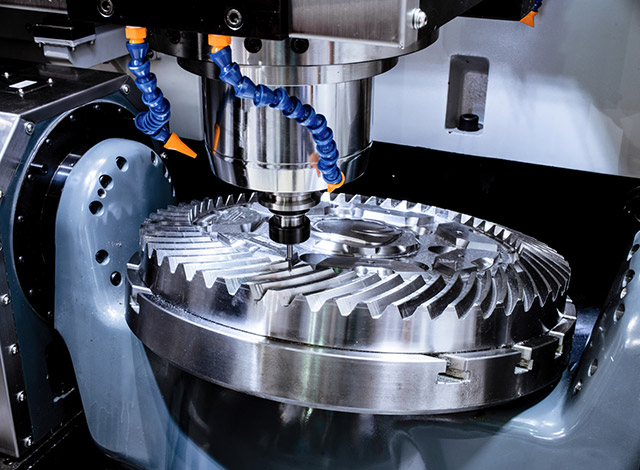

CNC

Sand Blasting

Anodizing

ED Coating

Electroplating

Liquid Coating

Micro-Arc Oxidation

Frequently AskedQuestions

Here is a collection of HF-TI visitors’ most frequently asked questions, if you have the same question, you can refer to it first.

What parts manufacturing services and materials options do you offer?

We provide die-casting, CNC machining, plastic injection, stamping and other manufacturing services to meet the diverse needs of our customers.

As for materials, we provide a variety of metal and plastic material options, including zinc alloy, aluminum alloy, stainless steel and various engineering plastics.

What is your quality control process?

How do your prices and delivery times scale based on order size?

Our prices and delivery times are adjusted based on order size and complexity. Large orders may receive more competitive pricing.

Do you provide sampling services?

Yes, we provide sampling services to help customers test and validate product designs.

How do you handle the shipping and logistics of your products, and do you have experience with international exports?

Yes, we have international export experience, and we will choose suitable transportation methods, including land transportation, sea transportation and air transportation to meet the needs of global customers.