Case Study

01

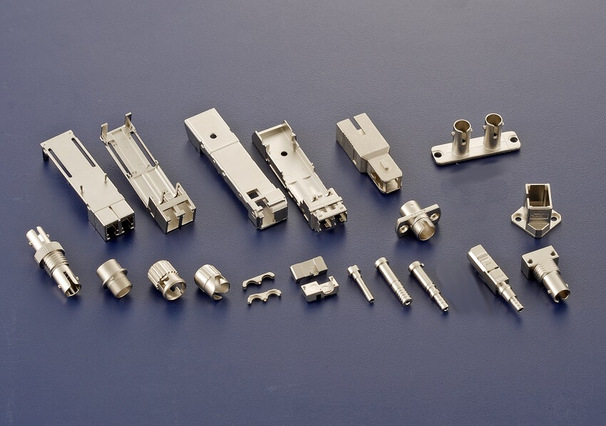

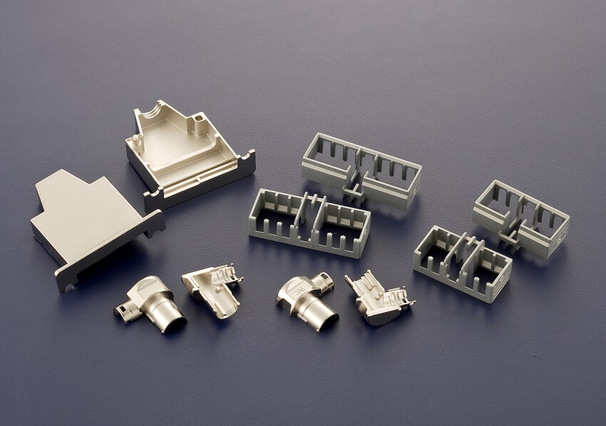

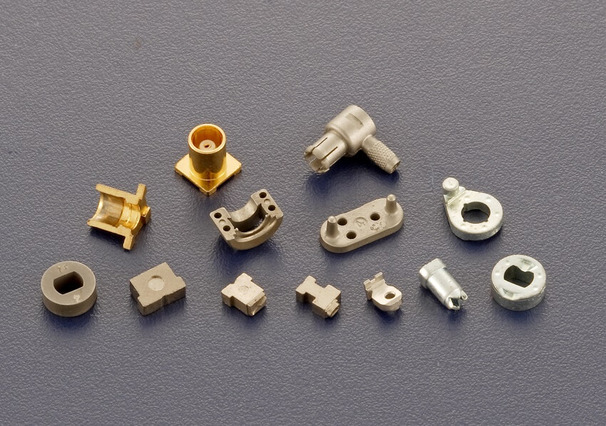

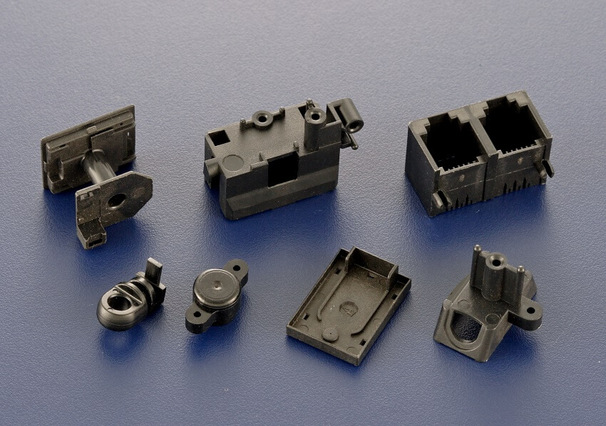

Connector Series Products

Zinc alloy connector products are ideal for electronic equipment connection solutions due to their high strength, corrosion resistance and superior electrical conductivity.

Their precise design and high quality zinc alloy materials ensure reliable electrical contact, and they are widely used in communication, automotive and industrial fields to provide stable and efficient connection performance for equipment.

For example: fiber optic, SFP, QSFP, RJ connectors, Bidi, D-Sub, HDMI, DVI, etc.

02

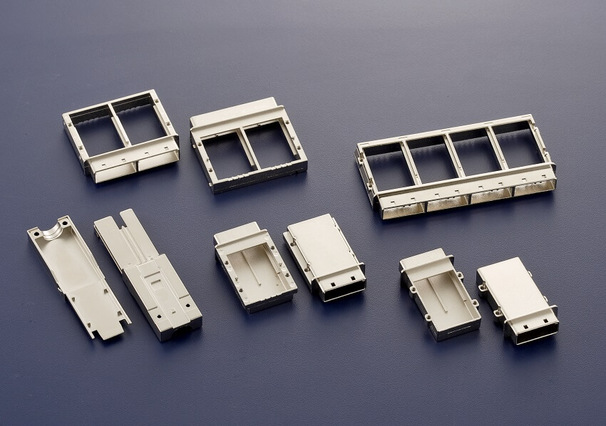

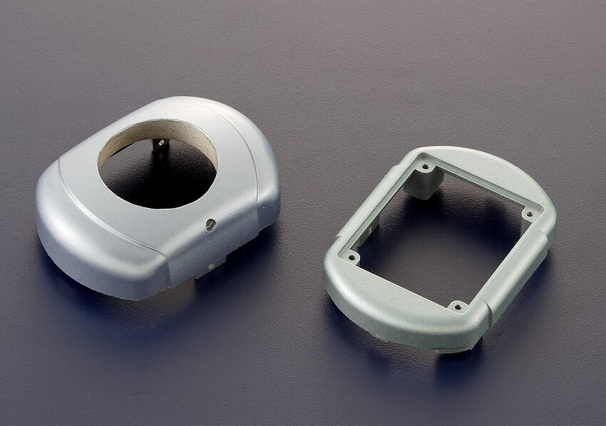

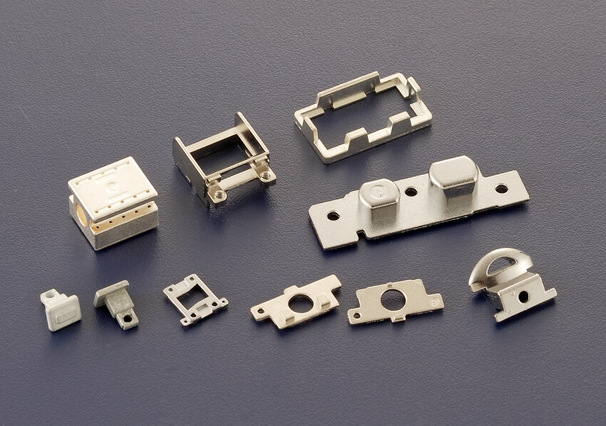

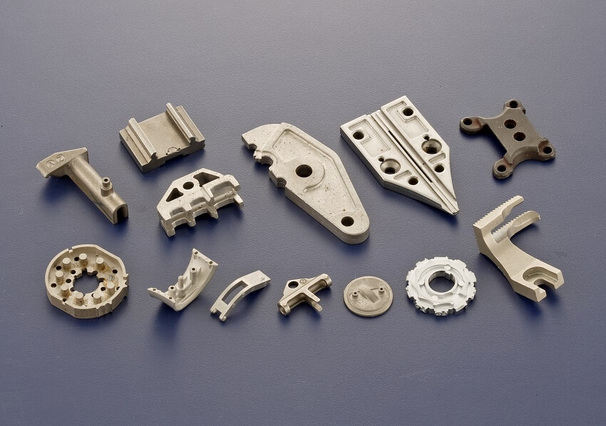

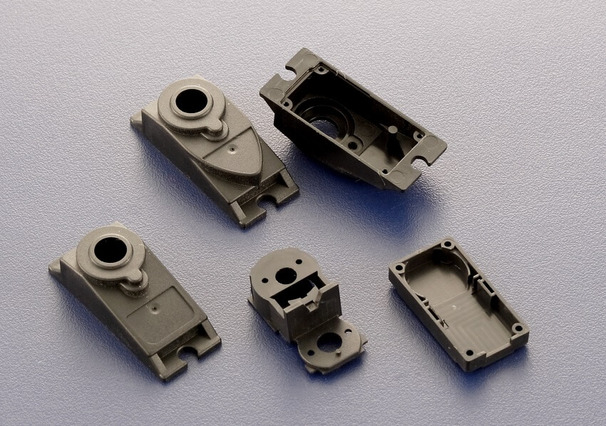

Electronic Components Products

Zinc alloys find applications in a wide range of electronic products due to their high strength, good thermal conductivity and corrosion resistance.

Different applications may require zinc alloy parts with different shapes and properties to meet specific needs.

For example: connectors, pushbutton connectors, heat sinks, RF components,and housings for consumer electronics such as cell phones, tablet PCs, headphones, cameras, etc.

03

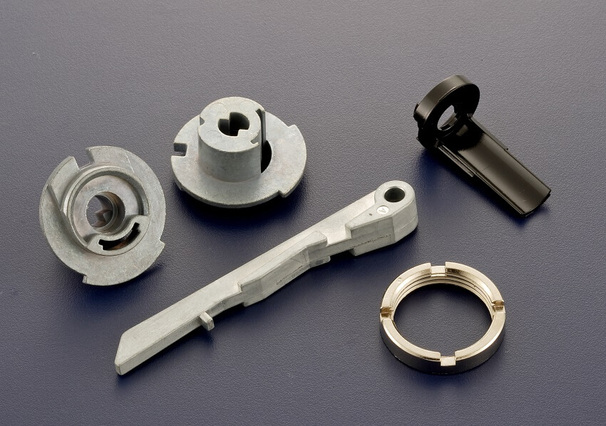

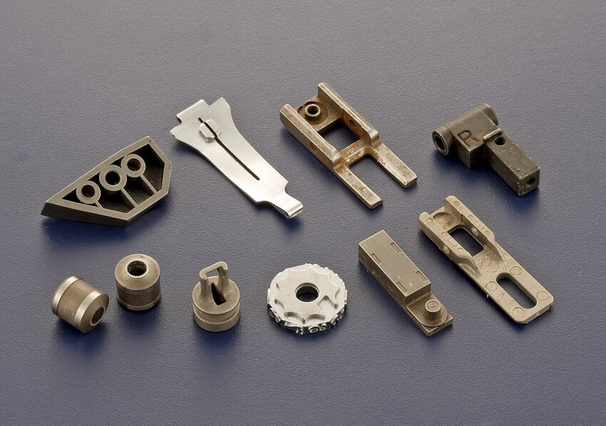

Lock Series Products

Zinc alloy’s high strength, malleability, and the ability to be coated with different protective coatings to further enhance its corrosion resistance make it an ideal choice for manufacturing locks that meet the needs of security, durability, and cost-effectiveness.

For example:door locks, vehicle locks, suitcase locks, bicycle locks, cabinet locks, electrical box locks, etc.

04

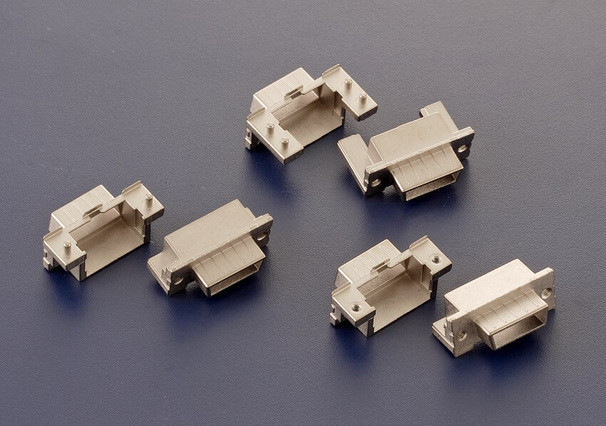

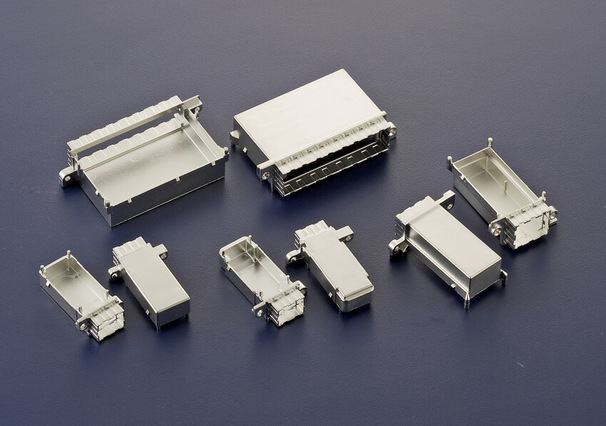

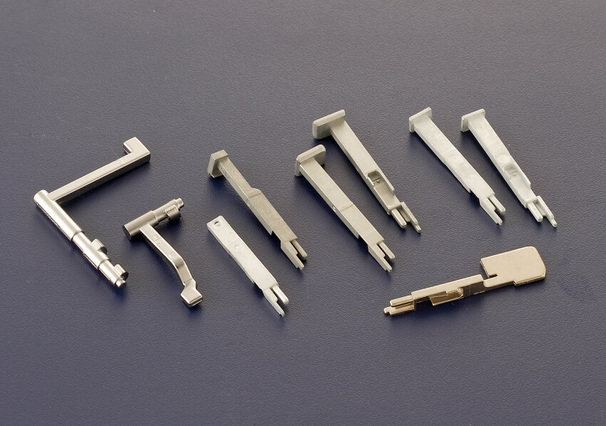

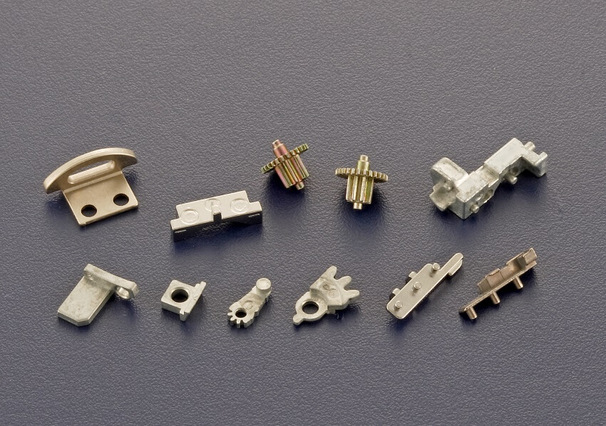

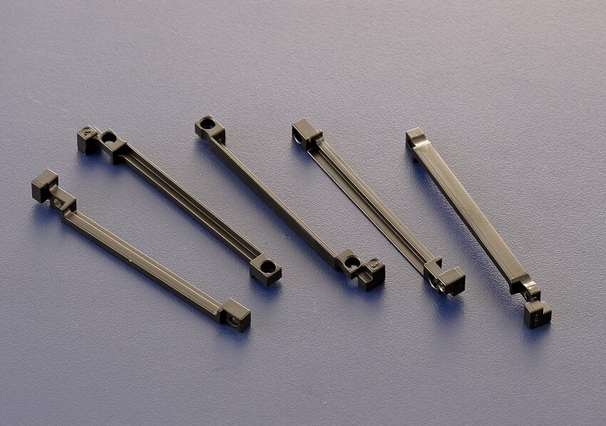

Mechanical Components Series

The selection of mechanical parts is usually based on the requirements of a particular application and the advantages of zinc alloys in that application.

In some cases, zinc alloys may require special treatments, such as surface treatments, to enhance their properties.

Different grades of zinc alloys may also be suitable for different applications, e.g. Zamak 3, Zamak 5, Zamak 8, etc.

05

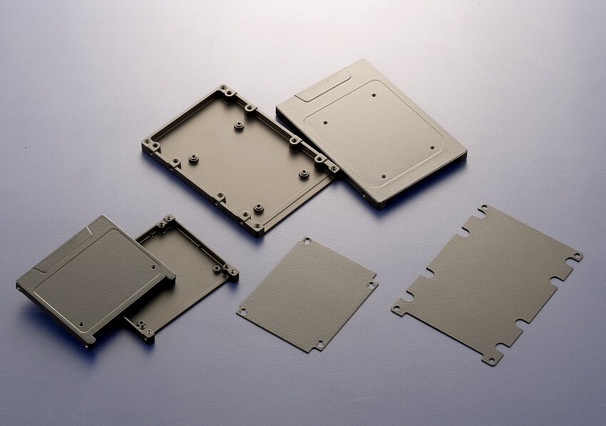

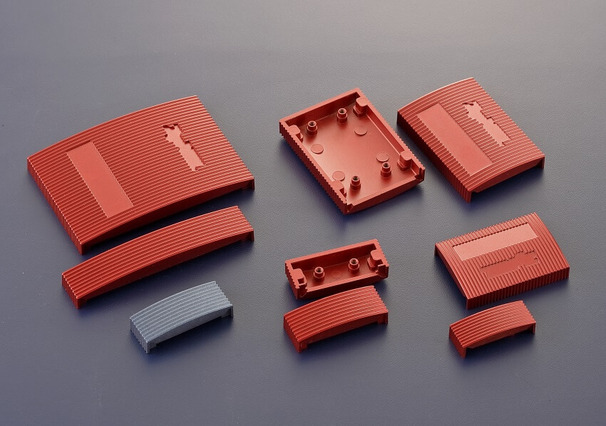

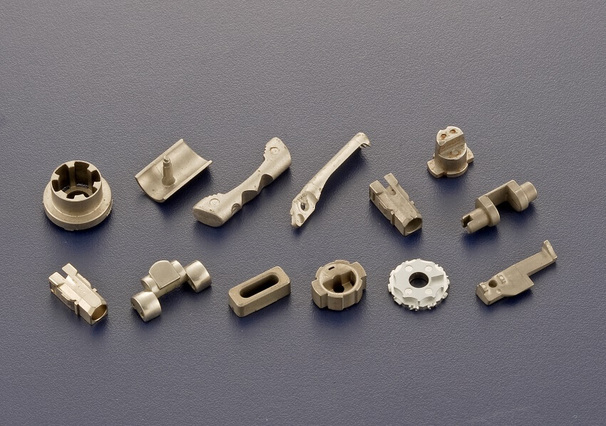

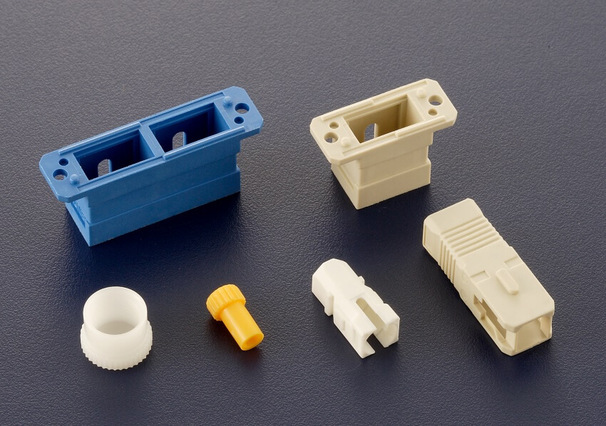

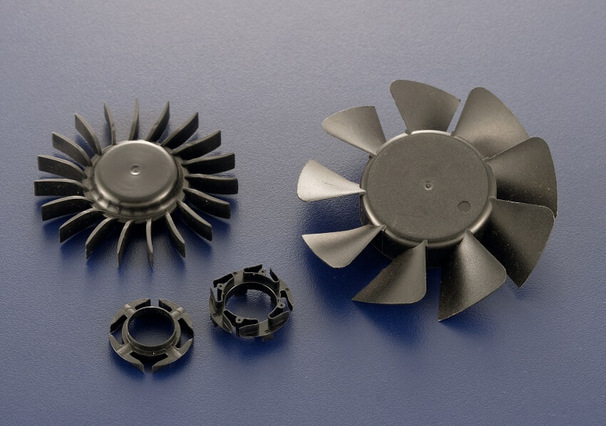

Plastic Injection Series Products

Plastic molding is favored for its efficiency, cost-effectiveness, and ability to produce complex shapes with minimal waste.

Different plastic materials are available to meet the needs of different applications.

Plastic injection molding technology is used in a wide range of industries, from appliances to automobiles to consumer products.

For example:electronic housings, automotive parts, industrial machinery parts, medical products, semiconductors, insert molded products, etc.

06

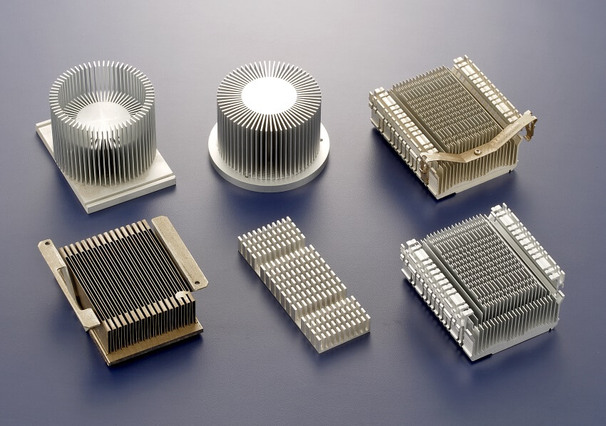

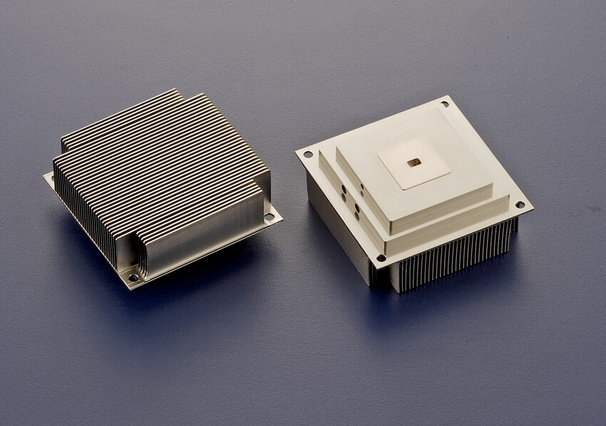

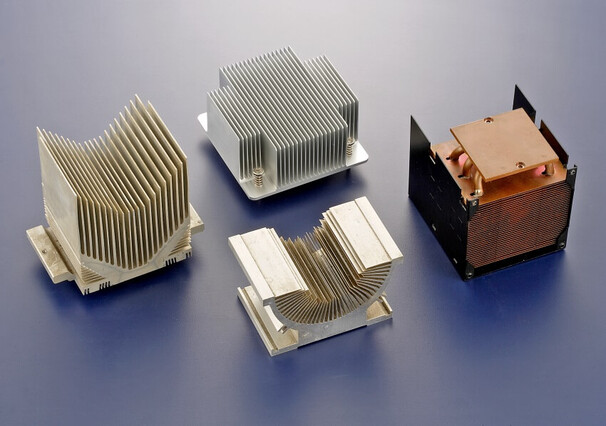

Aluminum Alloy Series Products

Aluminum alloys are alloys composed of aluminum and other alloying elements such as copper, aluminum, manganese and magnesium.

Aluminum alloys are one of the most important materials for lightweight, strong and durable products due to their superior performance characteristics.

For example:automobile parts, aerospace parts, electronic product housings, mechanical parts, sports equipment parts, etc.